Warehouse Management System

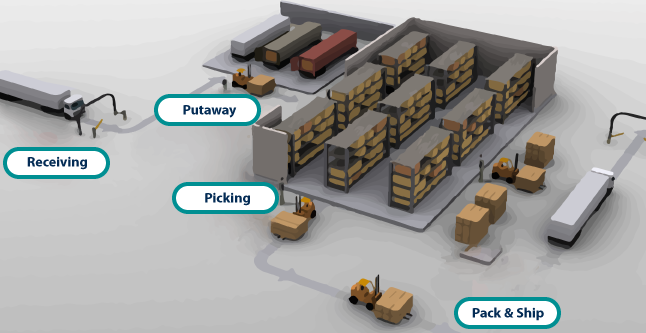

T3 is one of the best in class provider of ERP Warehouse management System in Mumbai which focuses on handling and replenishing goods under the roof of a warehouse, and the derived tasks to report and analyze inventory movements. Planned and actual inventory transactions are created by a particular demand for receiving or issuing goods. Any inventory movement results in a warehousing-system order to be executed. In fact, the warehousing-system orders are the communication layer between T3 ERP Warehouse and the other T3 ERP applications. As a result, tight integrations exist between T3 ERP Warehousing and the other T3 ERP applications, but at the same time the package is essentially decoupled from the rest of the T3 ERP applications. As a result, integrations towards external applications, such as WMS or ADC vendors, are possible.

-

Gate In

- - Advance shipping Note (API/Manual)

- - Barcode scan for gate in

- - QR Code Scan for gate in

- - Mobile App for Gate in scan

- - Auto allocation of staging area

-

Put Away

- - Storing material from staging area to storage location

- - Auto suggest storage location after scanning product.

- - Multiple product put away at storge location

- - Captures product barcode/qrcode during put away

- - Two-stage replenishment support

-

Sales Order

- - Multiple Sales Order Import

- - Manual Sales Order creation

- - Auto Sales Order creation via API from other ERP's

- - Generation of delivery challan

-

Vehicle Master

- - Auto Stock reservation against Sales order based on FIFO of manufactring date and weight

- - Reversal of stock after cancel the product

- - Once material is loaded dispatch will closed and invoice will raised

- - Slip is generated which contains product and its reserved location for pick

-

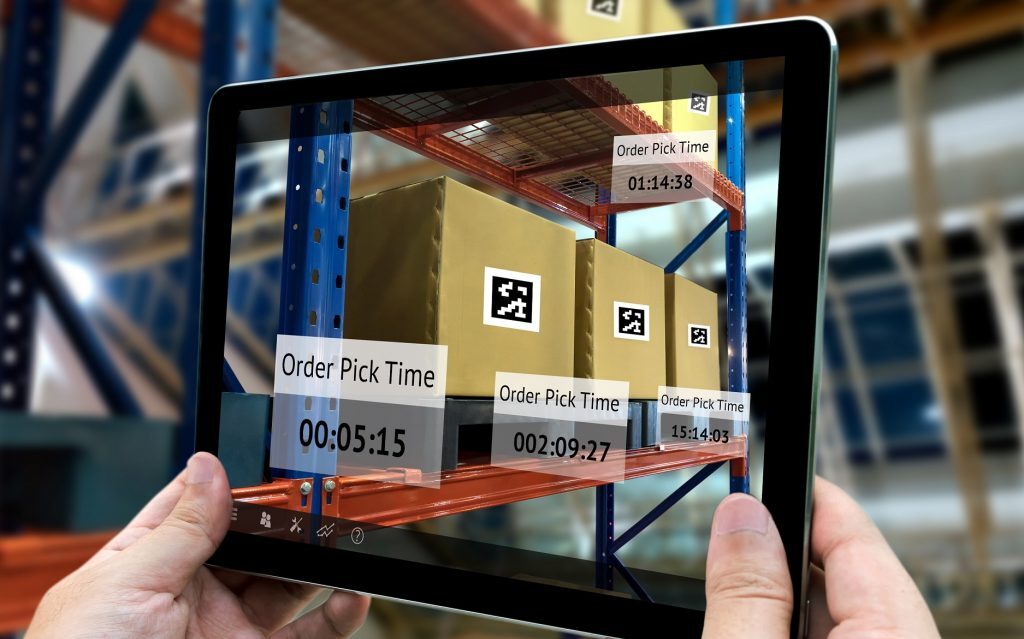

Picking and Packing

- - Pick product by scanning product and location

- - Drop picked product on loading area for load into vehicle

- - Material load into vehicle by scanning product

-

Warehouse configuration

- - Warehouse configure according Columns and Rows

- - Provde Graphical view of warehouse with location stock

-

Kitting and De-Kitting

- - Assemble and stock kits or parent items for future outbound shipments

- - Pick, pack, load and ship items from reserved or active locations. De-kit items from assembly locations

-

Shelf Life Monitoring

- - Use picking rules to monitor items’ shelf-life days

- - Specifies a 60-day shelf life restriction from the exact date of expiry

-

Work Order Management

- - Generate pickup instructions and match orders mentioned in the inventory

- - Create templates and fill out different parameters like route, item code or order number

-

Batch Picking

- - Manage warehousing picking tasks in batches through pick slip grouping rules

- - It streamlines bulk pick across deliveries or a single delivery